After a bit of a wait, my engine is back from the builder and we've put it in the car. Stil waiting for throttle bodies...

It's lovely and hot here. Proper english summer. Hot enough to melt wax, in fact:

No work is happening on the car.

A little trial fit of the front mounted oil cooler, the hard lines in the wheel arch, and the flexible lines that connect to the cooler.

On the other side of the engine bay, the oil tank is in and I have plumbed in the plumbing. So the oil console / thermostat / filter base is mounted, and I have connected it up to the fore-aft oil pipes that run through the sills to the front cooler:

The fuel system is now pretty-much finished.

For those who say they unwisely use my pics as reference, please note there is a deliberate mistake here. I do know that the outlet from the fuel filter is currently connected straight back to the return, rather than to the MFI pump (which I understand is the conventional scheme for those who like their engine to receive fuel). Before the engine goes in I will test it like this, just recirculating, to see if we have any leaks.

I've also got the engine tinware seal in (the one that goes around the perimeter of the engine compartment). Like all jobs involving rubbery bits, installing it was no fun at all. But I do quite like the cute little hole in the (Genuine Porsche) seal, for the fuel pipe - very neat and tidy.

With this scheme of employing professionals, it turns out I can sit in the garden drinking wine and work still happens on the car.

Don't know why I didn't think of this before.

Just for a few days, I’ve handed over to the professionals. When it gets back, the car will have dash, screens and headlining installed. Amateur hour will then resume.

Because I'm a genius, unlike those Porsche engineers, I've decided I can do better than them in a couple of areas.

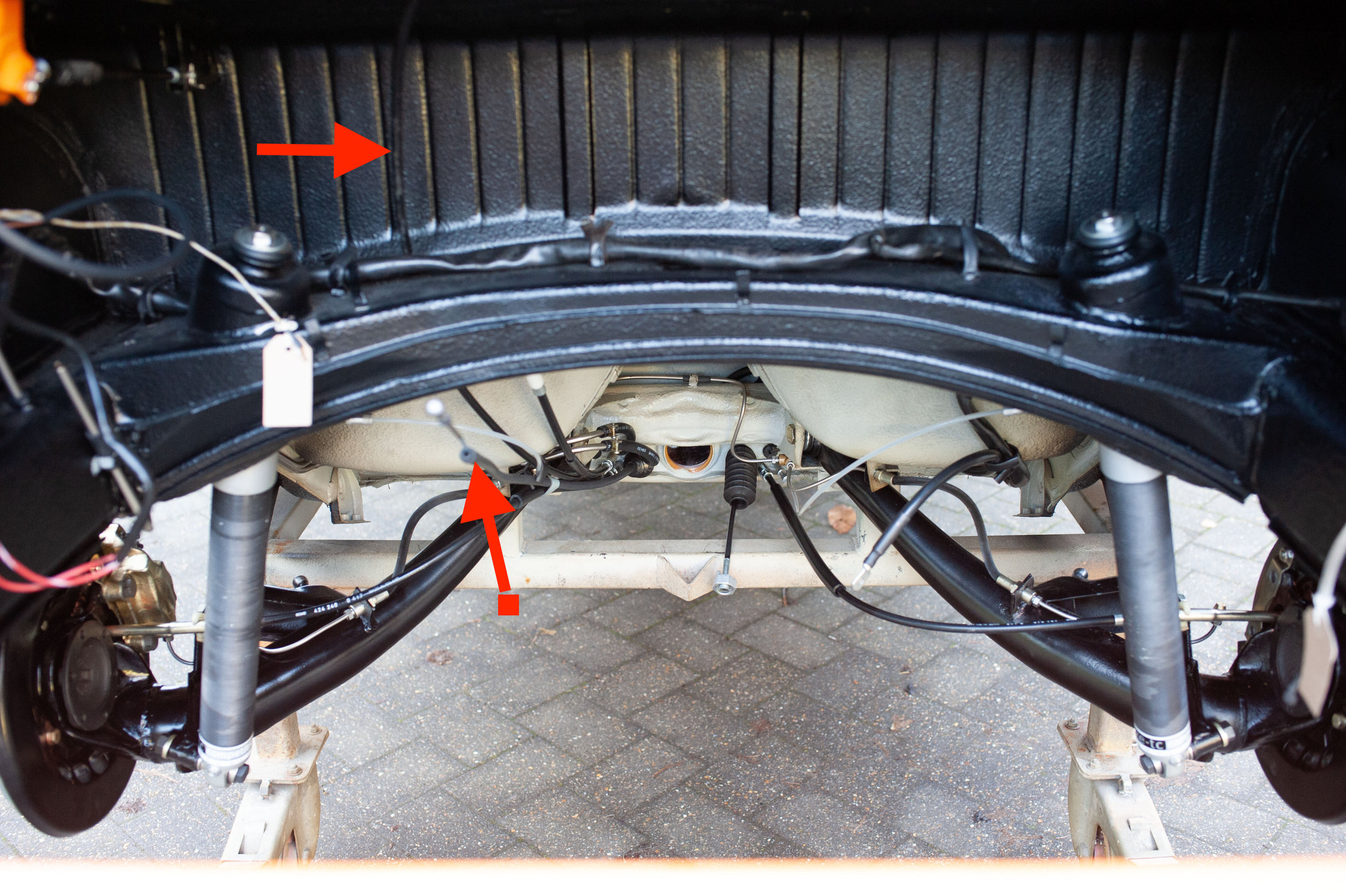

Hence the non-standard cables highlighted below:

The lower one in the pic is for the throttle.

I'm not a massive fan of the standard throttle linkage on a '70 car. It's an awful lot of parts to do a simple job:

Plenty to go wrong, in an area where going wrong can have unhappy consequences.

This thread on Pelican suggested an alternative scheme: http://forums.pelicanparts.com/porsche-911-technical-forum/309504-early-911-replacing-throttle-linkage-morse-cable.html

All the missing bits in this version of the diagram are replaced by a "Morse" cable:

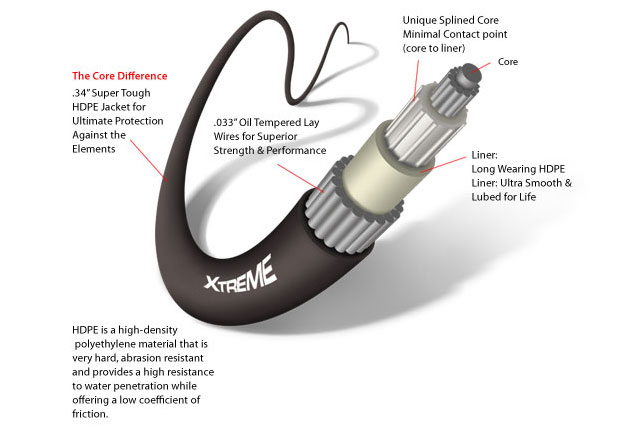

In my case the specific type of cable I have used is called a Teleflex TFXTreme. Most commonly used on powerboats, I believe, and available from your friendly local yacht chandlery. Incidentally in buying these it turns out that, although Yacht Tax seems to exist, it's nowhere near as ridiculous as Porsche Tax.

Anyway.... this sort of thing:

The advantages of this type are high quality materials (corrosion resistant) and, importantly, small bend radius - nominal spec is 100mm minimum, but (in new-out-of-the-box state anyway) they remain smooth well beyond that spec. Point is they are flexible enough to easily make the control run for the throttle.

Final note - obvs my genius statement is slightly tongue in cheek. In fact Porsche changed the design later on, to get rid of all that bell-crank on the side of the gearbox nonsense. So a 964 has a cable run fairly similar to mine (but less flashy cable).

Per the pics, the various fuel lines, brake lines, cables and electrical bits at the back end, and through the tunnel, are done.

They make the nice clean shell look really untidy.

I think my next resto might focus only on being nice to look at, so I can get rid of most of this clutter.

Oil and Fuel system refurbs are in progress. For the oil lines, the original fittings are all fine, and I think look much better than modern crimped versions. The old fittings are easy to work with and reuse. So what we see below is:

- original aluminium fittings, just vapour blasted. These are quite nice because they have the '69 date stamps

- original steel elbows etc, plated. Shockingly I have deviated from the original finish. I started by yellow zinc plating, but they looked pretty awful (surface finish not good enough). So these are now plated in satin nickel, with a base coat of copper. A bit like the standard chrome plating process. A bit blingy, but I like it.

- New hose, obviously. Cohline 2633.