But only on the inside, for now. It's going to be quite orange.

The paint is a custom mix. We found that the manufacturer's spec for my car's colour code (Signal Orange) was a really good match to my luckily-preserved original paint area (on the LH A-post, was preserved under the paint code tag in fact). But we needed to darken it very slightly to get it spot-on.

The photos are a bit deceptive - the colour is more orange, less yellow in real life and in daylight. Also it's not quite as glossy as it looks under the lights.

Again, based on reference photos of several original-paint cars, I asked Steve to replicate the factory stonechip finish. I'm very pleased with the way it's turning out.

The factory finish for seam seal was somewhat erratic and usually quite messy-looking.

For the areas that would have had factory sealant, I asked Steve to replicate the finish achieved by a production worker eager to knock off for a hearty lunch with free company beer. Other seams were also sealed, but more neatly.

I popped in at the weekend to discuss and agree textures of stonechip and seam sealer.

After my car, next in the queue for the DC magic is something properly exotic (Ferrari 275 GTB):

The main place I'm posting info about this restoration is the UK forum, DDK. http://www.ddk-online.com/phpBB2/viewtopic.php?f=28&t=48740

One very kind and knowledgeable DDK-er pointed out a bit of a cock-up. My fault, I did know about this detail, but had forgotten somewhere along the line.

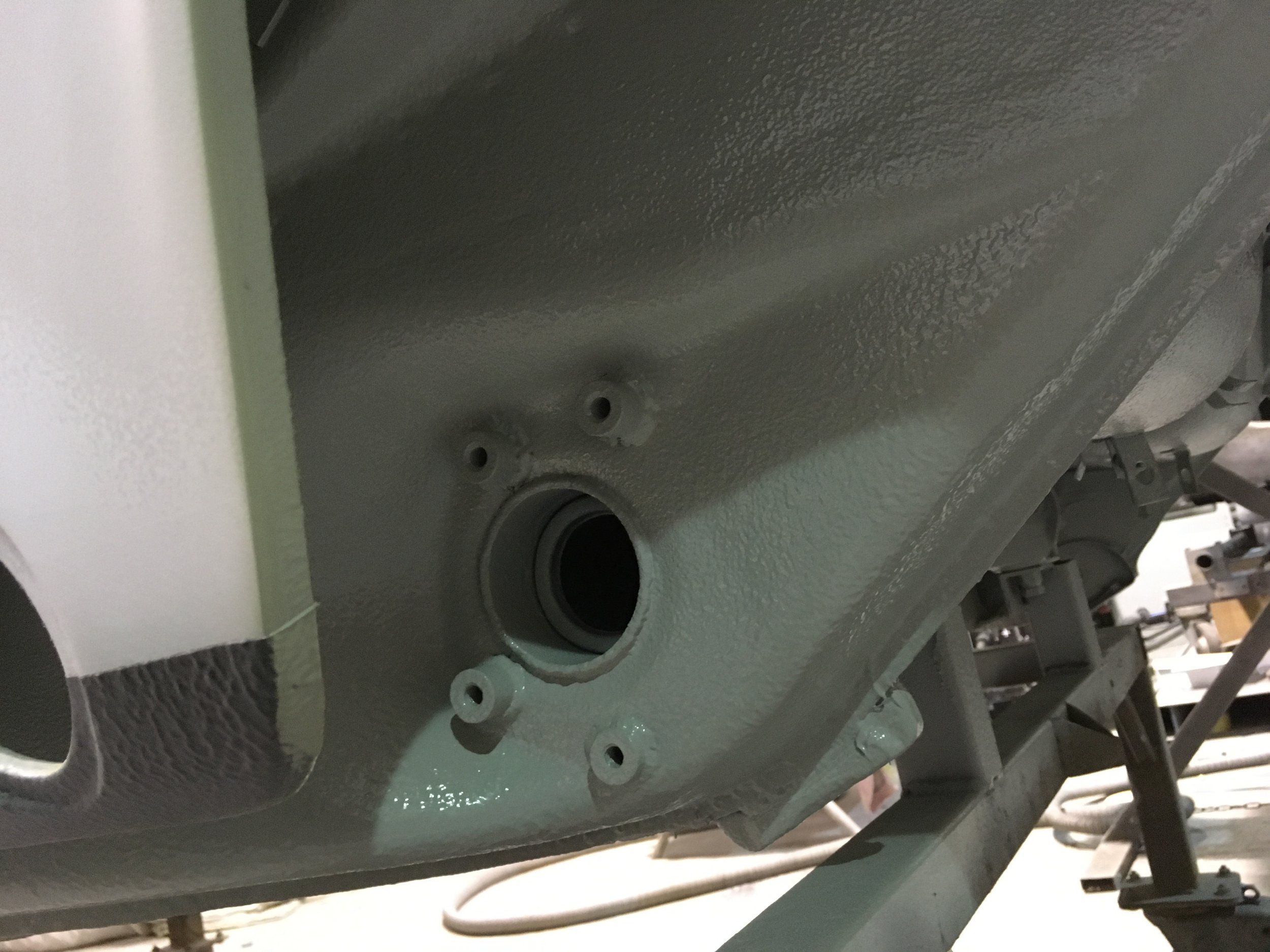

To elaborate, what's wrong with this picture? (my car):

Clues from some relevant reference photos of 70/71 cars. With thanks to Giovanni Favelli and David Conklin.

Yep, the cock-up is...

.... the highlighted drain holes are not correct for a 1970 car. I'm told they were introduced during the '73 model year.

You all knew that, right?

Now fixed:

Everything (including the new Porsche panels) has gone back to bare metal as the first stage of paint prep.

A skim of filler in places, but not tons of the stuff.

And some epoxy primer. Lovely and tough, offering much better protection against corrosion than was usual in 1969.

Barry took a little drive over to DC, to fit the modified rear bumpers and number plate panel. Fit was good, only minor tweaking required, and the end result is rather nice I think.

Here are a few pics of the shell in its current state.

The 1970 S had an aluminium deck lid and number plate panel. Deck lid already sorted, but the number plate panel needed some work. I bought a cheapie Restoration Design aluminium version to use as a starting point, and Barry set to work with the TIG welder.

Barry's comments on his work on this part:

Following the supplied template, I set about making the twin exhaust cut-outs.

There was no way I'd be able to free-hand these on an already made panel with the cut-outs right on the outer edge. After a bit of thought, I came up with a one-off tool that would do the job. In fact I did end up augmenting the tool with an additional dead-weight just to give a bit of stability.

I then used the tool to mark the fold and cut lines, and removed the metal not needed. The flanges were then formed. These terminated right on the vertical flange and would have been a weak-point, so these terminations were TIG-welded solid before sanding back out to blend in everywhere. I also TIG'ed the top seal holder on where the factory welds had already failed, as well as reinforcing various slip areas. The panel in places was paper-thin, so this was not a straightforward process!

With the main panel modified, I then pondered how to fix it to the two bumperettes. As specified, the exhausts run right through the existing brackets (which by now had been removed). I elected to use some thicker aluminium and fabricated a couple of brackets which were TIG welded into place. These have worked out very well, and have obviously now been drilled as appropriate.

The panel itself also needed quite a lot of basic fettling. They are pretty awful, but cheap and can be salvaged.

For various reasons, including a dalliance with some possible aluminium rear bumper corners (that didn't quite work out), I was pretty late getting the rear bumpers and number plate panel to Barry. In the end I bought new (steel) ones from Porsche. Not cheap, but the quality is good.

I asked Barry to do a bit of sports purpose modification before they went to paint:

Oooh yeah, I'm so creative. Surrey Outlaw styleeee:

My car will be painted by DC Coachworks in Hastings. They've done quite a few Barry shells in the past, which is an advantage. The required standard is understood, and they know they will get a decent base to work from.

As well as old Porsches, DC seems to do quite a lot of work for well-known Ferrari and Jaguar restorers. Steve at DC shared some photos of previous projects:

That 250 is my personal favourite. Here's my car, in good company, ready to start next week: